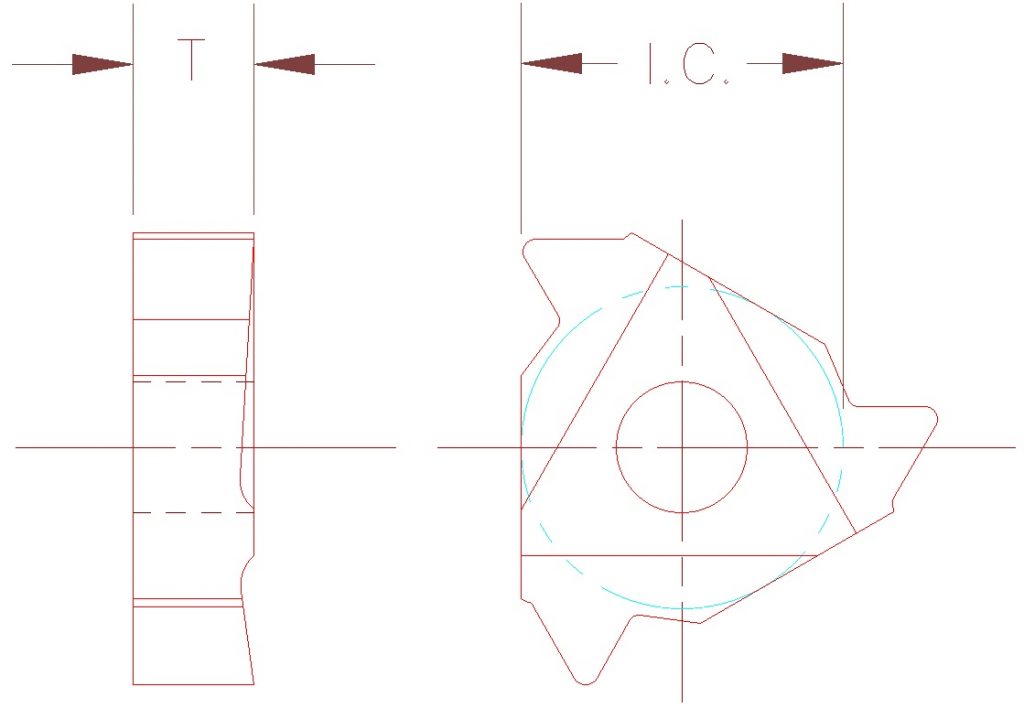

| *Catalog Number | API Connection Size | Pitch | Dimensions | |

|---|---|---|---|---|

| I.C. | Thk. | |||

| LT 43 8RD | 8RD. CASING 7 TUBING | 8 | 1/2 | 3/16 |

| LT 43 10RD | 10RD. CASING & TUBING | 10 | 1/2 | 3/16 |

| LT 43 5P. BUT 3/4 TPF | 4-1/2 – 13-3/8 BUTT CASING | 5 | 1/2 | 3/16 |

| LT 43 5P BUT 1 TPF | 16″ AND LARGER BUTT CASING | 5 | 1/2 | 3/16 |

| LT 43 8P BUT 3/4 TPF | 2-3/8 – 4-1/2 BUTT TUBING | 8 | 1/2 | 3/16 |

| LT 43 NV | 16°V-THD 8P & FINER | 8 | 1/2 | 3/16 |

| LT 54 V-0.038R 2 TPF | NC-23 – NC-50 | 4 | 5/8 | 1/4 |

| LT 54 V-0.038R 3 TPF | NC-56 – NC-77 | 4 | 5/8 | 1/4 |

| LT 54 V-0.040R 3 TPF | 2-3/8 – 4-1/2 REG. | 5 | 5/8 | 1/4 |

| LT 54 V-0.050R 2 TPF | 5-1/2 FH, 6-5/8 FH, 6-5/8 REG. | 4 | 5/8 | 1/4 |

| LT 54 V-0.050R 3 TPF | 5-1/2, 7-5/8, 8-5/8 REG. | 4 | 5/8 | 1/4 |

• H-90 and other special thread forms available on request..